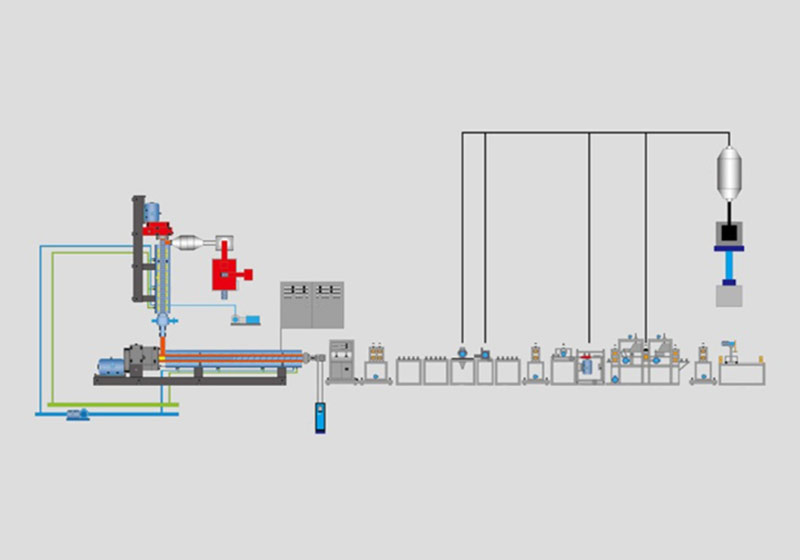

Ourgreen’s comprehensive XPS board production machinery is capable of making XPS boards to fit for any applications. Every production line model has the capacity to produce 300-1000kg/h of XPS foam boards. Experienced engineers design advanced machines and carefully assemble production lines. Our XPS board production lines consist of precise extruding system and recycling system for producing quality XPS board and enhancing ROI.

For a completely turnkey solution, we provide after-sales services and technical support to guarantee your efficient bulk production or help you carry out hassle-free distribution to global markets. Consult with our experts now to design personalized production lines to increase your XPS insulation board production.

Our machines efficiently produce quality XPS boards with systems handling multiple tasks to improve productivity.

Offering accurate material measurement and uniform mixing, our machines with Mettler Toledo dosing scales produce XPS boards consistently while making them match quality standards with ease.

A special injection system uses CO2 eco-friendly foaming agents to replace HCFCs and improve the compressive strength of our boards. We use TRICOR mass flow meters for accurate CO2 injection.

Multi-roller haul-off machines are for consistent flatness and shaping of our XPS foam boards. This way, our production lines mass produce accurately-shaped XPS boards at faster rates to meet demands.

XPS board scraps and powder generated during bulk production are processed by our Central Dust Collecting System to make workshops tidy and improve recovery efficiency.

We have different models for our production lines that are configured for varied XPS insulation board production requirements.

| Model | Capacity | Voltage | Required Space | Machine Weight |

|---|---|---|---|---|

| OGTS 75T/160 | ~400 kg/h | 380V 3 Phase | 46mx12mx6m | 18 tons |

| OGTS 85T/200 | ~700 kg/h | 380V 3 Phase | 50mx12mx6m | 20 tons |

| OGTS 95T/250 | ~900 kg/h | 380V 3 Phase | 50mx12mx6m | 22 tons |

| OGTS 110T/300 | ~1200 kg/h | 380V 3 Phase | 60mx12mx6m | 24 tons |

In carrying out full customization, we study your needs and mass produce XPS board solutions at affordable costs.

Considerate Custom Needs Analysis

Consult with our skilled R&D experts who study technical needs for increased productivity to identify the key features and custom options your production lines require. Our team takes insights from your design choices to construct efficient, long lasting machines to meet XPS insulation board production demands.

Contact our team today to see how our machines produce the right density XPS boards and yield more output at lower costs.

Experienced Machine Engineering

Our engineers have mastered the art of XPS board extrusion along with experience in production line manufacturing and assembly. Through advanced ISO9001 facilities, we create production lines from scratch with quality parts and handle XPS board production in our extrusion process.

Advanced CO2 technology is developed by our engineers to help factories produce safe and eco-friendly XPS boards while maximizing their overall quality. Engineers with expertise of polymer-based foams and machine manufacturing can support your any needs in your XPS board production lines.

Quality Guaranteed Commissioning

Our commissioning process determines the strength of our raw materials prior to complete manufacturing through a series of trial runs. Thanks to multiple patents, our laboratory possesses equipment for testing the capabilities of our boards and production lines.

Testing our production lines and XPS boards ensure normal operation and accurate mass production to earn high returns.

Technical Support

Offering lifetime consultation, our engineers have years of experience to be consulted on design, manufacturing and customization. Our consultation and technical training help your business to avoid unnecessary losses caused by long downtime.

To help save on business costs, we offer spare parts to replace damaged products. To further support your business, we provide on-site assembly and trial operation that guarantee smooth XPS board production that gives you higher profits.

Ourgreen provides our clients with a total turnkey solution from quotation to manufacturing and full-around after-sales services. For XPS foam boards factories, we even have bespoke production lines and fast-turnaround polystyrene materials to meet demand on any scale of production.

Hassle-free solutions we offered add value to every project and guarantee high ROI in machine investments and bulk XPS board purchase.

Throughout our all-around engineering, assembly, and commissioning, we manufacture production lines which are made to produce high-quality XPS foam boards suited to your budget and market concerns.

Applying a green production process and CO2 foaming technology that improve the material utilization, our machines can reduce your business costs while yielding higher profits.

In making our XPS board production lines efficient, we have experienced engineers that have designed complicated systems such as our CO2 technology to support all technical needs.

Highly-productive machinery carry out mass XPS board production for factories while ensuring consistent quality thanks to our engineering and commissioning expertise. With quality XPS foam boards made from our machines, manufacturers and wholesalers can reach wider audiences.

We create machines that produce consistently high-end XPS boards for a broad range of applications.

Copyright © 2020, Ourgreen. All rights reserved.